BENTHOWAVE INSTRUMENT INC. Acoustic Transducer & System

Impedance Matching between Transducers and Amplifiers

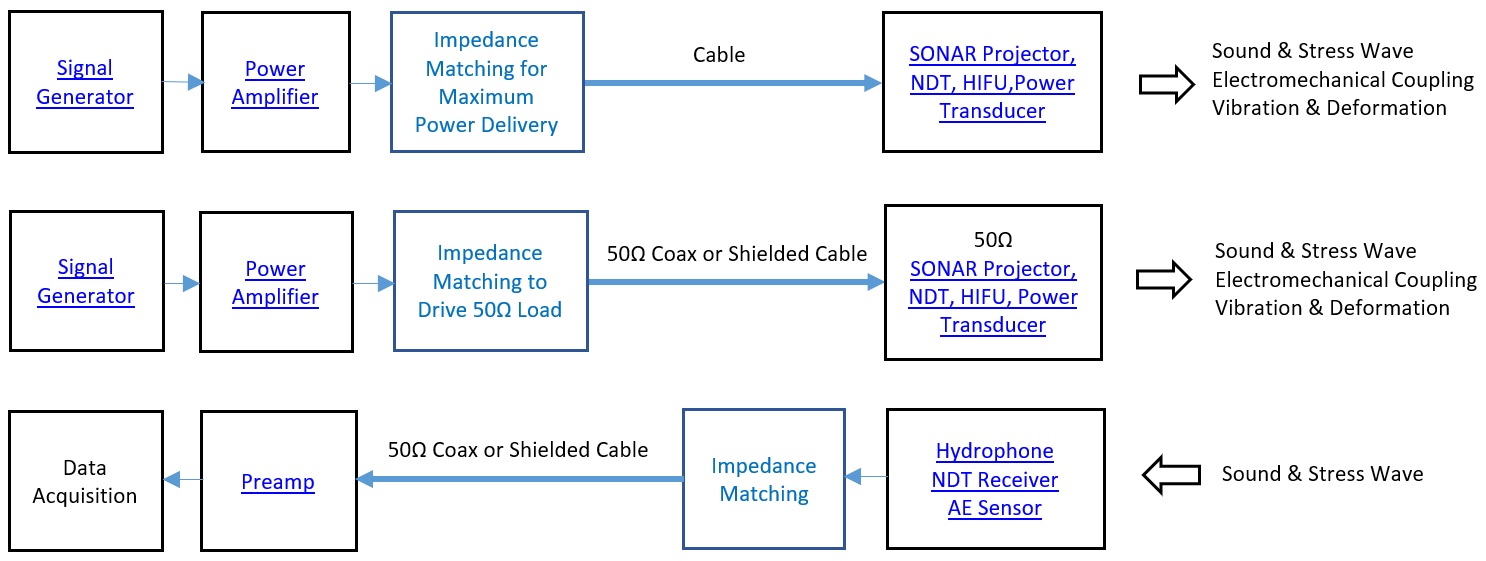

The complex impedance of a piezoelectric transducer (a projector or a hydrophone) is non-linear and frequency-dependent. Its magnitude ranges from hundreds kΩ to several Ω, and its phase varies from -90° to +90°. The transducer is a capacitive, resistive or inductive load at different frequency ranges. An impedance matching & tuning unit is a necessary device to change the complex impedance of the transducer in a specific narrow frequency range (generally around resonance frequency fs of the transducer) to meet the load requirements of a power amplifier for maximum and efficient power transfer from the electric to the mechanical, or to match the input impedance of a preamplifier for maximum and efficient power transfer from the mechanical to the electric, or achieve optimum source resistance for minimum noise figure NF. Generally, -3dB bandwidth of a transducer with impedance matching and tuning is greater than that of original transducer. Besides, broadband voltage step-up transformers are suitable for Study of dielectric, ferroelectric and piezoelectric materials.

| Related Products | |

| Power Amplifiers Driving SONAR and Ultrasonic (HIFU) Transducers | BII-2100 Transmit & Receive Switch: Sonar & Ultrasound |

| Transducers Broadband, High Power, High Temperature | BII-8070 Transmit & Receive Module: Sonar & Ultrasound |

| BII-8030 Portable Acoustic Transmitter | BII-8080 Portable Acoustic Transmitter and Receiver |

Impedance Matching between Transducers and Amplifiers

| Impedance Matching Unit | Refer to Datasheet. Bespoke small size and service temperature up to 200°C is available on request. |